In today’s fast-paced manufacturing environment, precision, speed, and efficiency are more important than ever. Coordinate Measuring Machines (CMMs) play a crucial role in ensuring dimensional accuracy during quality control processes. However, as technology evolves rapidly, many older CMMs become outdated—not because their mechanical structures are faulty, but because their software and controllers are no longer up to modern standards. This is where CMM retrofit software comes into play.

What Is CMM Retrofit Software?

CMM retrofit software refers to a specialized solution that upgrades the software system of an existing CMM to improve its functionality, compatibility, and performance. Instead of investing in a brand-new machine, manufacturers can opt to retrofit their existing systems with modern software platforms. This cost-effective approach extends the life of the machine, improves measurement accuracy, and enhances productivity.

Why Retrofit Your CMM?

1. Cost Savings

Retrofitting is significantly less expensive than purchasing a new CMM. While a new machine can cost anywhere from $50,000 to over $200,000, a retrofit might cost a fraction of that. This allows manufacturers to preserve capital while still gaining access to advanced features.

2. Improved Accuracy and Performance

Modern software algorithms are more precise and capable of handling complex geometries. By retrofitting your CMM with up-to-date software, you can benefit from enhanced performance, better data processing, and improved measurement reliability.

3. Compatibility With Modern File Formats

Legacy software often struggles with modern CAD formats. CMM retrofit software ensures compatibility with today’s most common file types (like IGES, STEP, and DXF), making it easier to import design data directly into the measurement process.

4. Extended Machine Life

The mechanical components of many CMMs, particularly granite tables and bridge structures, are built to last. Software retrofitting rejuvenates these machines, giving them a new lease on life and protecting your long-term investment.

Key Features of CMM Retrofit Software

When selecting a retrofit software solution, it’s important to consider features that will meet current and future measurement needs. Common features include:

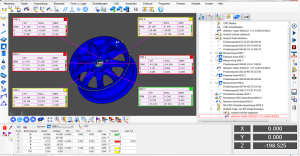

a. CAD Integration

Most modern retrofit software includes full 3D CAD integration. This allows operators to perform measurements directly on the CAD model, enhancing speed and reducing errors.

b. User-Friendly Interface

Legacy software can be clunky and hard to navigate. Newer systems offer intuitive interfaces with drag-and-drop functionality, touch-screen compatibility, and customizable layouts to improve operator productivity.

c. Advanced Reporting

Real-time data collection, customizable reports, and automatic generation of inspection results ensure that stakeholders have the insights needed for quality assurance and decision-making.

d. Multi-Probe Support

Modern software supports various probing systems, including touch-trigger probes, scanning probes, and laser probes, offering flexibility in inspection methods.

e. Automation and Scripting

The ability to automate inspection routines through scripting or macros saves time and reduces manual errors, especially in high-volume production environments.

Popular CMM Retrofit Software Solutions

Several companies offer retrofit software tailored for different CMM brands and configurations. Here are a few popular solutions:

1. PC-DMIS

PC-DMIS by Hexagon is one of the most widely used CMM software packages. It offers powerful 3D measurement capabilities, CAD model integration, and support for a wide range of probes.

2. MODUS

Offered by Renishaw, MODUS is designed for high-performance scanning and is compatible with a variety of CMM hardware. It includes powerful data analysis and graphical reporting tools.

3. CMM-Manager

CMM-Manager is a highly cost-effective solution for Windows-based systems. It supports tactile and non-contact probing and offers an easy-to-learn interface suitable for both novices and experts.

4. Metrolog X4

Metrologic Group’s Metrolog X4 provides high-end 3D metrology capabilities with an emphasis on speed, precision, and automation.

The CMM Retrofit Process

Step 1: Assessment

A thorough evaluation of the existing CMM system is essential. This includes hardware inspection, controller compatibility check, and identifying existing limitations.

Step 2: Controller Upgrade (if needed)

Sometimes, in addition to software, the controller must be replaced. Modern controllers allow better communication between the software and hardware, resulting in improved speed and functionality.

Step 3: Software Installation

The new software is installed and configured to match the specific needs of the facility. This may include custom user settings, probe configurations, and integration with other enterprise systems.

Step 4: Training

Operators and quality control personnel are trained to use the new interface and tools. Most retrofit vendors offer on-site or remote training sessions.

Step 5: Calibration and Testing

The final step involves calibrating the CMM using standard artifacts to ensure accuracy. Test runs are performed to validate performance improvements.

SEO Benefits for Manufacturers Offering CMM Retrofit Services

If you are a company offering CMM retrofit software solutions, it’s vital to maintain strong SEO practices to ensure visibility in search engine results. Here are some best practices:

– Use Relevant Keywords

Integrate keywords like CMM retrofit software, CMM upgrade services, coordinate measuring machine software, and CMM software solutions into your content, meta tags, and headers.

– Publish Case Studies

Case studies showcasing before-and-after scenarios can improve credibility and drive traffic from potential clients seeking similar solutions.

– Optimize for Local SEO

If your services are location-based, ensure your Google Business profile is optimized and include city-specific keywords.

– Create How-To and FAQ Content

Publishing guides, tutorials, and FAQs related to CMM retrofitting can position your brand as an authority in the field and improve organic traffic.

Challenges and Considerations

While retrofitting offers numerous benefits, it’s not without challenges:

- Compatibility Issues: Not all legacy machines can be retrofitted without major modifications.

- Downtime: Retrofitting requires machine downtime, which can affect production schedules if not properly managed.

- Initial Training Curve: Operators need time to adapt to the new system, especially if switching from a vastly different interface.

Conclusion

Investing in CMM retrofit software is a smart, cost-effective strategy to modernize your quality control processes without the heavy price tag of new machinery. It allows manufacturers to stay competitive by leveraging modern technologies on proven mechanical platforms. With the right software and professional support, a retrofitted CMM can deliver precision, speed, and reliability for many years to come.